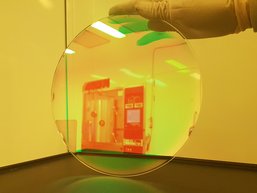

Our thin film deposition laboratory offers custom design and manufacturing services to researchers and companies. Our experts can design the coating that best suits your needs and optimize the manufacturing process. Our technologies offer great flexibility in terms of composition, thickness, density and number of layers to produce many components such as mirrors, optical filters and many more. Contact us for an assessment of the feasibility of your project.

Technologies

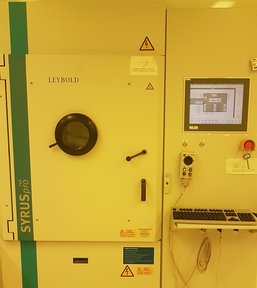

LEYBOLD SYRUS PRO 710

Oxide: Ti3O5 , Ta2O5 ,HfO2 , Al2O3

Silica: SiO2

Evaporation by electron beam assisted by an ion plasma (APS) with in-situ optical measurement of the thickness (400-2500 nm); deposit of multilayers (max 100).

INTLVAC NANOCHROME

Targets: Ta, Al, V, W, Nb, Si

Reactive gases: O2 , N2 , C2H6

AC-double magnetron sputtering of metal sources followed by oxide/nitride deposition by the ion source; deposit of multilayers (max 100) of optimized density.

OTHER SYSTEMS

- Intlvac Nanochrome: Thermal evaporation system and electron beam dedicated to thick layers and infrared materials.

- Electron beam evaporation system for deposition (SiO2, ZnS, MgF2, YbF3, Al2O3, etc.).

- Thermal evaporator by Joule effect for deposition of Cr, Au, Al, Ag, Cu dedicated to the manufacture of metallic mirrors and plasmonic layers.