Pavilion of Optics and Photonics

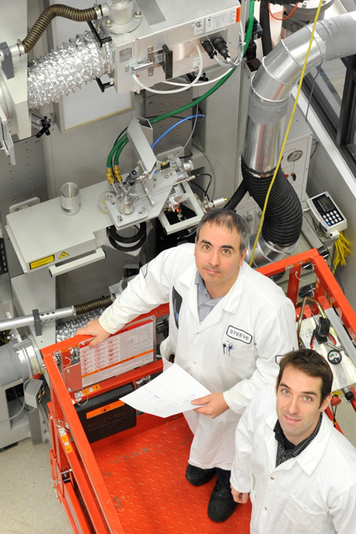

Inaugurated in 2006 at Université Laval, the prestigious Pavilion of Optics and Photonics (POP) which is the first infrastructure of this type in a Canadian university, is exclusively dedicated to research in the field of light sciences. The laboratories section houses around 100 optical laboratories covering approximately 4,500 square meters, 80% of which are class 100,000 or higher clean rooms. Several architectural components allowing the control of ambient conditions and the reduction of vibrations make it a first-class environment in which to carry out cutting-edge research.

The pavilion also has administrative premises with an area of approximately 3,000 square meters offering workspaces for nearly 150 students, around 30 teachers and 50 employees. The administrative centre of the COPL and the Quebec strategic cluster that bears the same name is also located in this pavilion. The POP also hosts several meeting rooms as well as an auditorium that can seat 100 people.

Bringing together a critical mass of expertise combined with the pooling of resources within the POP further ensures the excellence of the COPL's research work. State-of-the-art infrastructures and instruments are made available to all our research teams as well as to the centre's institutional and industrial partners. The expertise of our researchers combined with the pooling of resources within the POP further ensures the excellence of research work.

Clean Rooms

More than 200 m2 of class 1000 and 100 clean rooms are dedicated to microfabrication and thin film deposition activities. The services resulting from the multiple commercial and custom-made instruments of this laboratory (thermal evaporators, spray chambers, rapid thermal annealing, mask aligner, centrifuges, reactive ion etcher) are in support of all the research work of the COPL. Some equipment can be used by students after a few hours of training.

Deposition of Thin Layers

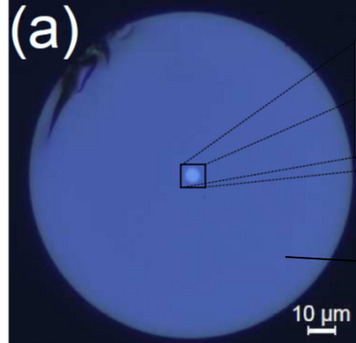

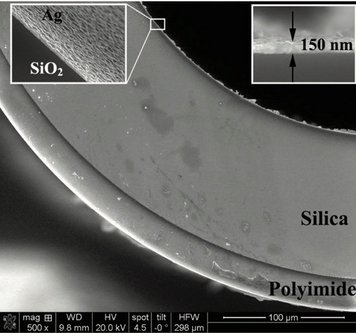

COPL's two main thin-film deposition equipment incorporate state-of-the-art plasma-assisted electron beam vaporization (Leybold Syrus Pro) and cathode sputtering (Intlvac Nanochrome) technologies. They allow the fabrication of thin metallic layers as well as multilayer coatings of metal oxides and semiconductors. It is therefore possible to custom design and manufacture a wide variety of mirrors, optical filters and coatings operating at wavelengths from ultraviolet to mid-infrared. These manufacturing capabilities are complemented by photolithography equipment as well as a dual-beam scanning electron microscope (SEM) with ion etching and precious metal nanodeposition capabilities.

For more information on these infrastructures and the associated services: Deposition of Thin Layers

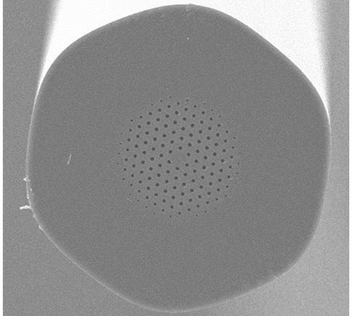

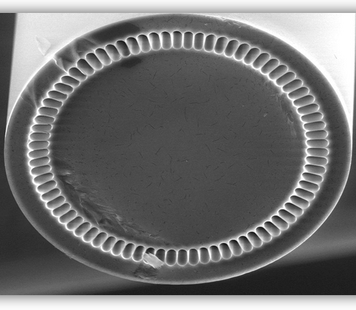

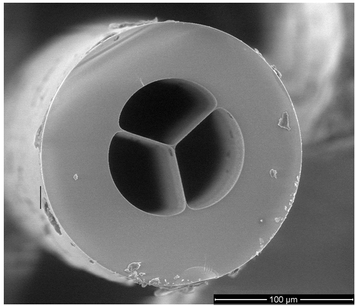

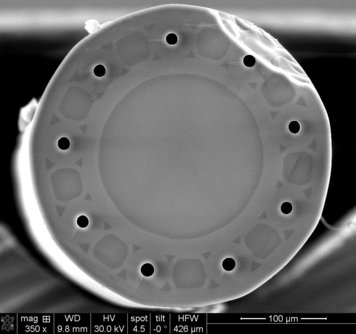

Manufacture of Optical Fibers

COPL's expertise in the synthesis of vitreous materials, the design and manufacture of optical fibers and the development of photonic devices are unique in Canada and world-class. The COPL is home to the first university laboratory in Canada that manufactures glass preforms and optical fibers.

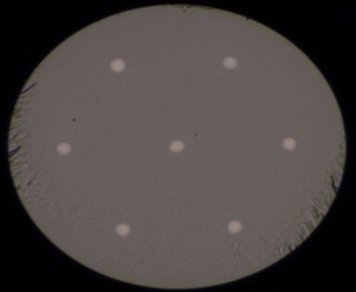

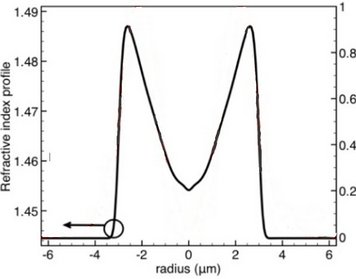

The MCVD (Modified Chemical Vapor Deposition) process laboratory includes two glass towers (SG Controls), one of which is equipped with capacities for the synthesis of silica preforms by MCVD processes, as well as a doping and chemical etching station. The MCVD preform synthesis process is also complemented by a vapor phase deposition and in-situ doping (Chelate) unit which makes it possible to achieve higher concentrations and a better distribution of dopants in the glasses, compared to doping in solution.

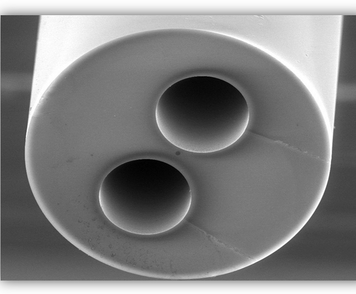

The two drawing towers, one dedicated to silica optical fibers and the other reserved for fibers of special materials (i.e. polymers, low temperature glasses, chalcogenides, multi-materials, etc.) complete this unique infrastructure and offer versatility unmatched in specialty fiber optic manufacturing. This infrastructure is regularly updated with improvements to equipment and the development of technical and scientific expertise. These special optical fibers are then integrated into photonic devices such as sensors, amplifiers for telecommunications networks and fiber lasers as part of the work of the COPL research teams as well as during projects in partnership with companies.

These facilities are directly linked to the development of the “Guided Optics and Optical Fibers” research axis and allow the manufacture of a multitude of different types of fibers to serve the research work of the COPL and its partners.

For more information on infrastructure: Optical Fiber Design and Fabrication

This laboratory houses several pieces of equipment used for fusion, cleaving, stripping and re-sleeving of optical fibres, including five fusion machines, each of which uses its own fusion technology. This equipment is complementary and makes it possible to work with a wide variety of optical fibers in support of work on the development of fiber devices and fiber optic lasers.

Manufacture of Optical Elements

The optical element manufacturing laboratory offers complete manufacturing and characterization services for custom-made mirrors, lenses and other optical components for the benefit of COPL research work and projects in partnership with companies.

A four-axis digital lathe (Precitech Nanoform 250 Ultragrind) integrating diamond-tipped turning and roughing (grinding) capabilities is used to machine spherical, aspherical and freeform shapes in glasses, polymers and metals with sub-micrometric precision. If necessary, the machined surfaces can then be optically polished via seven-axis CNC polishing equipment (Zeeko IRP-200) which allows the surface roughness to be reduced to a few Ångströms while correcting the precision on the form to levels ranging from at λ/10.

This laboratory also contains a profilometer (Taylor Hobson PGI Freeform) and a Fizeau-type interferometer (Zygo Verifire HD) for the analysis of machined surfaces.

For more information on these facilities and related services: Optical Elements

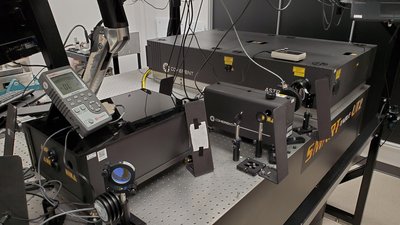

Femtosecond Laser Chains

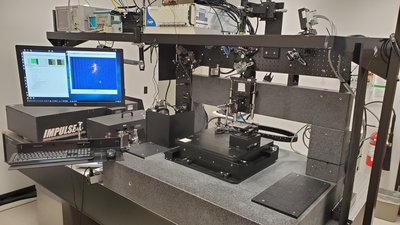

Four femtosecond laser chains are distributed in the COPL laboratories. These laser chains emit pulses of up to several millijoules of energy at repetition rates of a few hertz to 20 megahertz. They are coupled with multiple other equipment and devices (frequency doubling crystals, optical parametric amplifiers, multi-axis motorized translation assemblies) thus offering an ideal working environment for projects relating to laser-matter interaction and component inscription photonics in glasses.

Characterization

The COPL has a vast array of characterization instruments available to all research groups. The state-of-the-art technologies used are refined year after year and expert technicians ensure their optimal operation. Although expert technicians are dedicated as operators, the instruments can be used by students following a short training.

In order to ensure the quality of the optical systems and their components, the COPL has acquired a series of metrology and optical characterization instruments. This state-of-the-art equipment is available to users and guarantees optimal performance of innovative technologies.

- Spectrofluorimeters

- UV-Vis-NIR Spectrophotometers

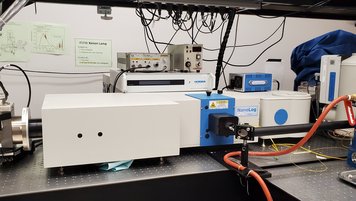

- Fourier Transform Infrared Spectrometer (FTIR)

- Interferometers

- Optical microscopes with phase contrast observation

- Fluorescence microscopes

- micro-Raman microscope

- Infrared and hyperspectral imaging

- Index profile analyzers for glass preforms and optical fibers

- Optical spectrum analyzer covering from ultraviolet to mid-infrared

- Vector and optical communication network analyzers

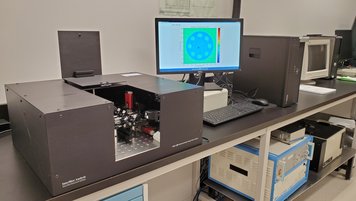

- Autocorrelation of laser pulses and beam analyzers

- Bragg grating interrogators

- Characterization of photonic microchips

- Measurement of the refractive index of thin layers

- Test bench for lenses and optical systems

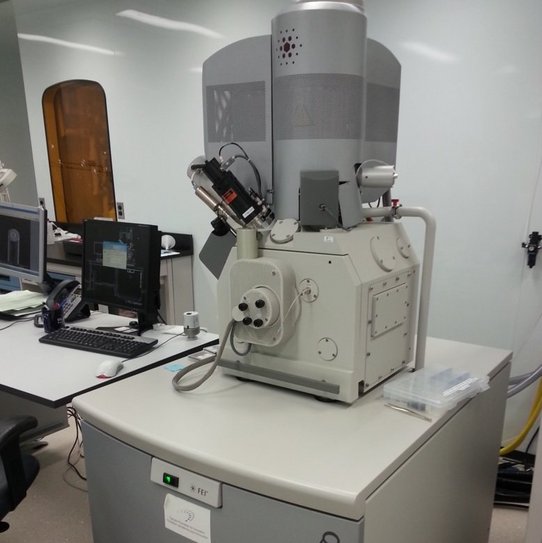

The COPL has a scanning electron microscope available to its members and partners. This very powerful and versatile tool integrates several useful functionalities in observation, characterization and manufacturing of optical and microelectronic components.

- Observations in low vacuum and high vacuum modes at nanometric resolutions

- Ion etching by focused ion beam

- X-ray spectroscopic analysis

- Platinum and gold nanodeposition

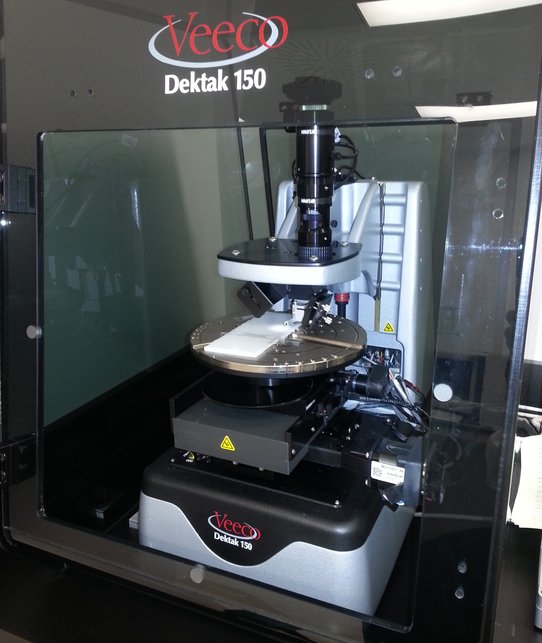

For the characterization of surface topography and 3D reconstruction, the COPL has equipped itself with state-of-the-art instruments. The equipment available is as follows:

- Dektak profilometer for the topography of any surface

- Taylor-Hobson profilometer for lenses and optical components

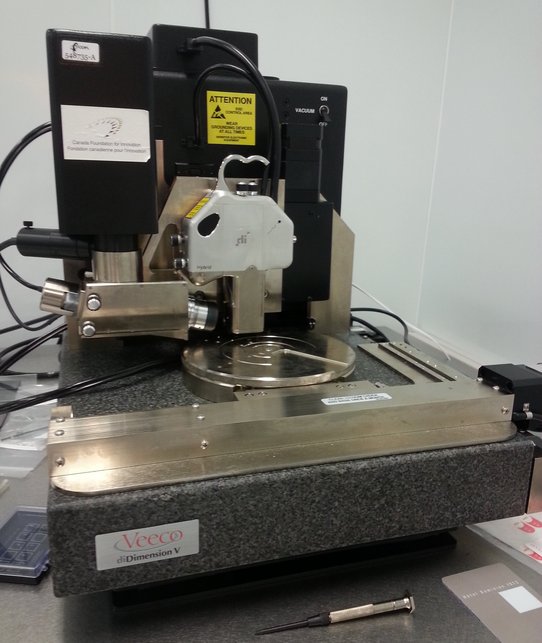

- Atomic Force Microscope for Diffraction Gratings and Photolithographically Treated Surfaces