The COPL has clean room infrastructures that allow it to offer microfabrication services to researchers and companies. While some standard equipment is made available to external users, other more specialized ones are operated by expert technicians whose training and experience will allow customers to take full advantage of all the features available. Contact us for an assessment of the feasibility of your project.

Infrastructures

Deposition by centrifugation

- Spinners for deposition by centrifugation (spincoating)

- Cleaning stations, chemical etching and thermal annealing

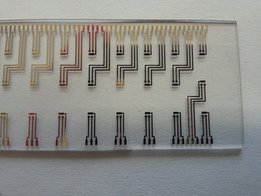

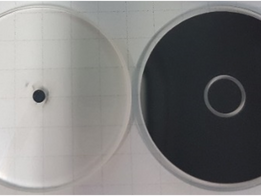

Photolithography

- Mask aligner for exposure at 365 nm

- 0.8μm resolution

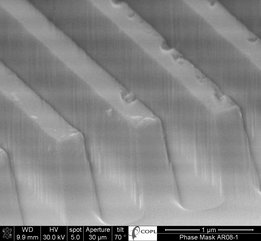

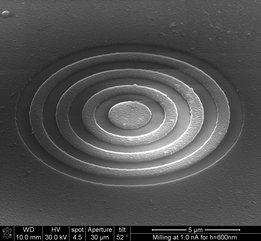

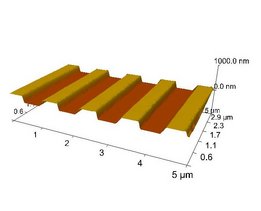

Reactive Ion Etching

- 2 PlasmaTherm 790 systems for quartz and chalcogenides

- Substrates from 50 to 200 mm

- Etching rate 20 nm/min

- Depth down to 1 μm